Welcome to Generating Better – technical experts in risk reduction and performance improvement for offshore wind O&M. We have been providing O&M services to the offshore wind sector for over ten years and we are working around the globe to support our clients to develop better projects and helping to plan, operate and maintain offshore windfarms to improve their performance.

Our experience is rooted in practical understanding of how offshore windfarms are operated – our team have direct experience of power plant operations at offshore windfarms. We provide O&M Strategy advice and we are also driving improved knowledge sharing and innovation in offshore wind and have strong links with leading universities and Innovation Centres of Excellence.

About us

Generating Better was formed in 2012 by Sally Lockwood. Our consultants have hands on experience rooted in practical understanding of Offshore Wind Farm Operations and Maintenance. We understand the challenges and risks in the O&M phase for large renewable energy plants and can help to mitigate risks and drive high performance. We work closely with owners, investors, suppliers and regulators to help deliver performance excellence.

Our Services

We provide early project O&M concept studies, O&M port feasibility studies and contract development support. We also provide specialist support to Technical Due diligence Teams and continue to provide support to operational wind farms.

Our Work

Generating Better specialises in O&M development, operational excellence, shareholder advisory, and skills training. Generating Better is working across the globe and has supported projects in the Europe, Asia, the USA, and Australia.

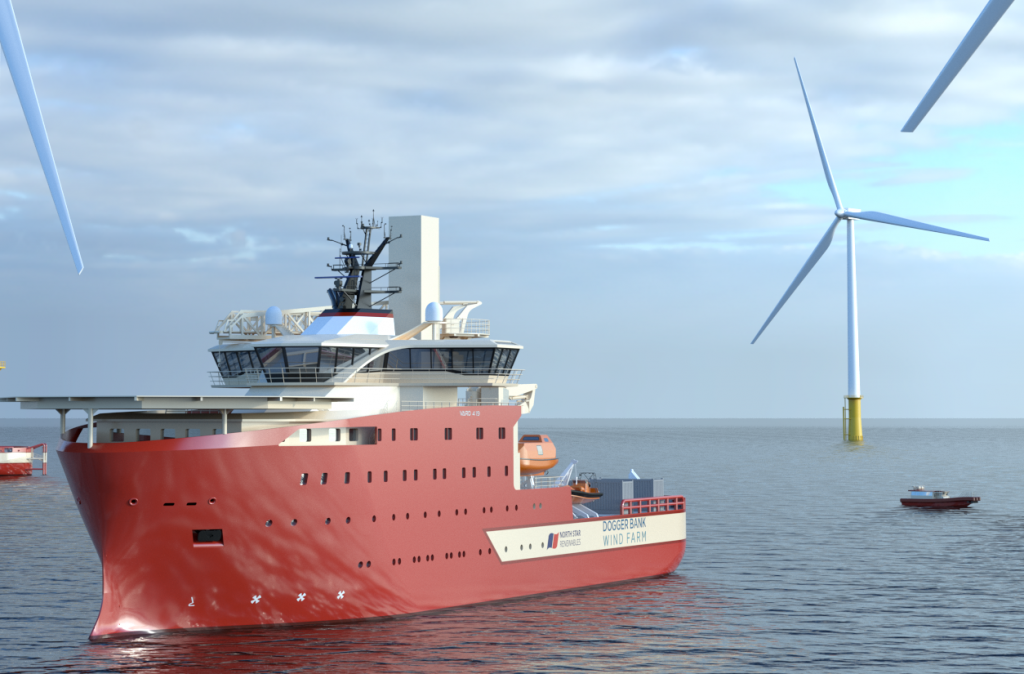

Gallery